Tearrific Five: The Journey of Building an Automated Tea Brewer

- Aiden Lim

- Feb 25, 2025

- 5 min read

Updated: Feb 26, 2025

1. Our Chemical Device

Introduction

Tea brewing requires precise temperature and duration control for the best taste and texture. Many tea drinkers struggle with inconsistency and the inconvenience of manual brewing. Our team, Tearrific Five, set out to solve this problem by creating an Automated Tea Brewer that ensures precise temperature and time control while being user-friendly, efficient, and sustainable.

Device Overview

Our Automated Tea Brewer allows users to control the brewing process with a push of a button, eliminating human error. It features a twist-lock brewing chamber, a slider dispenser, and an LCD interface that guides the user through the process. The device ensures optimal extraction of flavors and aromas while maintaining a sustainable and safe design.

Sketch of our Design:

Team Planning, Allocation and Execution

Team Members and Roles

CEO: Keith Lai

Deputy CEO: Aiden Lim

COO: Chloe Lai

CFO: Shashini Rau

CSO: Thalia Chai

Groups Finalized BOM List and Gantt Chart

Design and Build Process

Design Evolution

Our design process started with function analysis and early sketches, followed by concept evaluation. We refined our ideas using Fusion 360 before moving on to fabrication.

Building the Prototype

Planning Phase:

Finalized component selection.

Assigned responsibilities based on expertise.

Fabrication Phase:

3D Printing key components: twist-lock mechanism and slider.

Twist Lock Mech Laser Cutting acrylic pieces for the body.

Assembly of the structure using glue and screws.

Integration Phase:

Arduino Coding: Programmed buttons for precise control of brewing time.

Electronic Wiring: Connected the LCD, pump, and control buttons.

Final Product:

My Contribution:

I did everything other then 3d printing and fusion 360.

Problems and Solutions

Challenges Faced

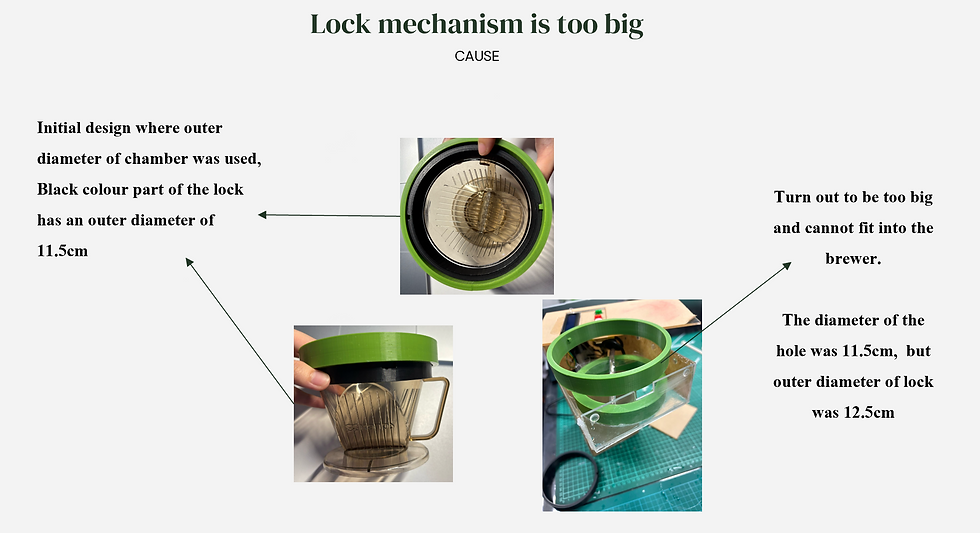

Lock Mechanism Too Large

Cause: Used the outer diameter instead of inner diameter for measurements.

Solution: Adjusted size in Fusion 360 and reprinted the part.

Slider Mechanism Had Leaks

Cause: The gap between the chamber and slider wasn’t airtight.

Solution: Applied hot glue and Blu Tack to minimize leakage.

Buttons and Wires Protruding

Cause: Poor cable management.

Solution: Used ice cream sticks for better button pressing and created a cardboard frame for the LCD.

Acrylic for body was too small

Cause: Under cut

Solution: Recut

5. Project Design Files as Downloadable Files

All Fusion 360 files, .dxf files, .stl files, and Arduino program files can be downloaded here:

6. Team Learning Reflection

1. Communication and Collaboration:One major challenge we faced was ineffective communication within the group. Some members were unclear about their tasks but did not speak up, and as a group, we failed to identify their struggles early on. Despite having a Gantt chart to guide our progress, we did not adjust our pace to support those who were lost. Moving forward, we must create a more open environment where everyone feels comfortable seeking help and providing updates.

2. Planning and Motivation:The planning of our Gantt chart was another area for improvement. It was primarily created based on one member's input without gathering feedback from the entire group. As a result, some members felt unmotivated because they were not involved in setting the timeline. In future projects, we should ensure that everyone contributes to the planning process so that the schedule reflects the group’s collective capabilities and commitments.

3. Leadership and Progress Tracking:The group leader (CEO) could have monitored progress more frequently instead of waiting until deadlines. This lack of regular check-ins caused confusion and disorganization, resulting in faulty parts and misaligned efforts. Frequent progress reviews will help keep everyone on track, identify issues early, and ensure consistent output from all members.

4. Material Selection:Our choice of acrylic for the project also presented challenges. Acrylic is not a flexible material, and we encountered issues such as difficulties in bonding parts due to its smooth surface. This experience taught us the importance of researching and testing materials before making a final decision to avoid similar setbacks in future projects.

5. Material Dimensions and Accuracy:Lastly, we made an error in our material measurements. We failed to account for the thickness of the acrylic, which caused fitting issues. For future projects, we will ensure proper dimensioning by including allowances for material thickness to achieve accurate fittings and better-quality assemblies.

6. Personal Learning Reflection

Teamwork is often seen as the foundation of a successful project, where individuals collaborate, contribute their best efforts, and work towards a shared goal. This project, however, highlighted the challenges that can arise when teamwork is not as effective as expected. It served as a reminder that clear communication, accountability, and shared responsibility are crucial in ensuring a smooth workflow.

Challenges in Leadership and Task Execution

Every role in a team carries its own responsibilities, and effective leadership plays a key role in guiding a project to success. However, this experience showed that leadership is not just about holding a title—it requires active participation, decision-making, and problem-solving. Without these elements, progress can slow down, leaving other team members to take on additional responsibilities.

Similarly, task execution requires attention to detail and thoroughness. Missteps in completing assigned work can lead to delays and extra effort from others to compensate for what was missed. This project underscored the importance of double-checking work, following through with assigned tasks, and seeking help when necessary to ensure that everything is completed as required.

Time Management and Commitment

Time management is a critical skill in any project, and balancing multiple responsibilities is something every team member faces. While challenges and competing priorities are inevitable, planning ahead and managing workload effectively can make a significant difference in the quality of work produced. This project demonstrated how varying approaches to time management affected the overall progress and quality of deliverables.

Final Thoughts: A Learning Experience

This experience has been an insightful lesson in teamwork, emphasizing the importance of accountability, effective communication, and collaboration. While challenges arose, they also provided valuable takeaways on patience, adaptability, and the need for clear expectations in group work.

Moving forward, I will take these lessons to heart, striving to work with teams that prioritize commitment and shared effort. At the same time, this project has reinforced the value of proper planning, proactive problem-solving, and the importance of every member contributing equally to a common goal.

A little note to myself in the future: Choose your teammates carefully, or be prepared for a tough ride. Not every friend makes a reliable teammate, and sometimes, the people you trust the most will disappoint you in ways you never expected. Next time, take a step back, assess wisely, and think twice before forming a team—because nothing makes a project more exhausting than having to carry the weight of an entire group on your own.

Comments